Mount Sicker: copper, gold, silver, zinc prospect near Duncan, BC

SUMMARY

- Historical mining between mainly 1895-1915, with cut-off grades at 8% copper

- At least 300,000 tons of acid-generating waste rock and a number of other hazards were left behind

- A no-chemical, closed-loop ore sorting process would remove over 95% of sulphides from the rock, including gold, copper, silver and zinc, but also mercury, arsenic, lead and sulphur

- Potentially highly profitable, low cost with rapid implementation and completion

- No new “mining” would be done, hazards would be addressed, and the site would finally return to nature after over 100 years

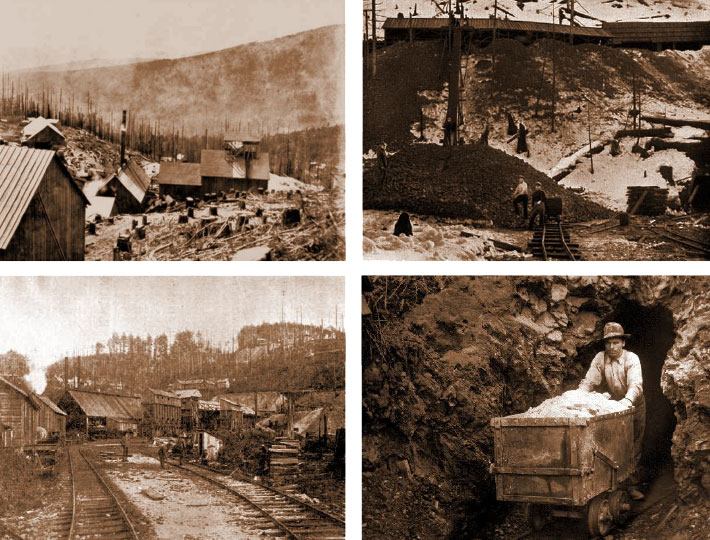

MOUNT SICKER

Waste Rock

.

- Over 300,000* tons of waste rock may be sitting at the old mining sites on Mount Sicker.

- Previous operations on Mount Sicker include Lenora, Richard III, Tyee, Victoria and Twin J mines (1895-1945) – this work has left behind massive amounts of waste rock.

.

*Potential quantities and grades are conceptual in nature. There has not been sufficient exploration to define a mineral resource, and it is uncertain if further exploration will result in the target being delineated as a mineral resource.

WASTE ROCK

MOUNT SICKER

HAZARD CLOSE UPS

*For example, in the event that adits are discovered to now be local bat habitat, there are special screens that will allow bats continued access while blocking human access

MOUNT SICKER WORK COMPLETED

Grid Sampling

- 97 grid-pattern surface samples returned average grades of: 1.86 g/t Au, 48.6 g/t Ag, 1.22% Cu, and 3.05% Zn, across an estimated 250–350 kt of waste rock.*

Grades May Improve With Depth

- 30 hand/auger samples, excavated to depths of 2–3 metres, returned materially higher grades, averaging: 3.95 g/t Au, 79.17 g/t Ag, 3.25% Cu, and 5.72% Zn, indicating potential vertical grade improvement within the waste rock pile.*

Surface Mineralization Among Waste

- An exposed outcrop within the waste rock pile was sampled with 5 continuous channel samples, returning an average of: 5.6 g/t Au, 122 g/t Ag, 6.25% Cu, and 7.7% Zn, highlighting the presence of locally high-grade sulphide material.*

Ore Sort Testing

- A 528kg ore-sorting test produced high-grade material averaging 6.43 g/t gold, 180 g/t silver, 4.92% copper and 8.7% zinc, with a projected 30–40% mass pull from waste, potentially yielding about 100,000 tonnes of high-grade material.*

Acid Testing on Waste vs. Sorted Material

- Acid testing on our 528kg sorted sample showed that the ore sorting process transformed acid generating waste into benign rock. Raw waste rock was acid generating but once sorted, rejected material was non-acid generating.*

.

*Potential quantities and grades are conceptual in nature. There has not been sufficient exploration to define a mineral resource, and it is uncertain if further exploration will result in the target being delineated as a mineral resource.

PROCESSING POTENTIAL

- 300,000 tons of waste or more, all in piles at surface and easily accessible

- Average values at surface of 1.86 g/t gold, 48.6 g/t silver, 1.22% copper, and 3.05% zinc (overall averages may be higher*)

- A 528kg ore sorting test-run returned high-grade material with 6.43 g/t gold, 180 g/t silver, 4.92% copper and 8.7% zinc

- Overall mass pull from waste expected to be in the 30-40% range, producing approx. 100,000 tons of high-grade material

- High-grade material will be trucked off-site and sold

.

*See Press Releases dated March 27, and October 9, 2024

ACID TESTING

- Testing was performed on waste before and after being run through the ore sorting process\

- Existing waste scored 0.2 neutralization – highly acidic

- Post sorting, remaining waste scored 5.3-6.3, which is “normal”

- PH levels went from 6.3 to 7.2 – again, acidic to normal

- Overall, 95% of contaminants were removed, including lead, arsenic, mercury and sulphur (but also gold, copper, silver and zinc)

PERMITTING PROCESS

- Permitting process is underway.

- The Province/community has a vested interest in addressing the waste and hazards.

- Sasquatch has submitted detailed surveys, processing plans, and a reclamation/closure strategy, all from qualified professionals.

- The site is currently a waste dump, with environmental and potentially lifethreatening physical hazards.

- The goal is to remove the high-sulphides, address the hazards, improve water runoff quality, and make the site safe for recreational use.

- Community, local government and First Nations have expressed support.

MOUNT SICKER

LOW CAPITAL INVESTMENT REQUIRED TO ACHIEVE CASH-FLOW

.

- Processing partners are being evaluated to provide technical support and the required ore sorting equipment

- Once permitted, first delivery of 10,000 tons of high-grade material to port could occur within weeks

- Significant cash-flow could be achieved with minimal initial capital, some of which could be obtained through grants, debt, or other non-dilutive means

MOUNT SICKER

WHY WE THINK THIS APPROACH COULD BE “THE MODEL” GOING FORWARD

Previous attempts to address waste-rock at old mining sites generally suggest small-scale processing on-site, which has issues:

- Requires MORE mining infrastructure, including new tailings ponds, which increases the mess.

- Takes many years before ANY reclamation can be done.

- Creates new environmental risks.

Sorting and shipping of highgrade has the following big advantages:

- All done using mobile infrastructure, with no “new” mess – uses an existing off-site facility for advanced processing.

- Can be completed within months so reclamation can begin almost right away.

- Removes harmful contaminants with the valuable minerals, improving the water/soil quality and allowing new growth.

Carbon Footprint & Environmental Benefits

- No faster or more environmentally friendly way to get critical minerals into the supply chain.

- Copper, silver and zinc may be used to support clean-tech technology (EV’s, solar, batteries, etc.).

- No new mine, no new processing facility required.

- All this while addressing ongoing environmental hazards.

- Future point – Carbon footprint comparison? Discovering and extracting a pound of copper the traditional way vs. reclaiming.

The Mount Sicker Reclamation Project (and our other projects) are expected to:

- Provide jobs.

- Clean up significant environmental hazards.

- Result in the recovery of gold, silver, copper and/or zinc.

- Address a number of potentially life-threatening hazards.

- Represent a rare ‘win-win’ environmentally and economically.

- Serve as an example of how to deal with waste sites nationwide.